When I began my career as a maintenance strategy consultant and RCM facilitator in the 1990s, we used techniques such as Reliability Centred maintenance (RCM) and Failure Modes and Effects Analysis (FMEA) to analyze assets such as oil platforms, pipelines and petrochemical plants to determine appropriate maintenance strategies for each piece of equipment. There were essentially three strategies to choose from.

- Reactive – fix it when it breaks, and hold a spare if downtime is a concern

- Preventive – try to predict the safe or useful life of each piece of equipment based on analysis of past lives of similar equipment, then intervene at a pre-determined point in its lifecycle to refurbish or replace equipment thereby resetting the lifecycle clock

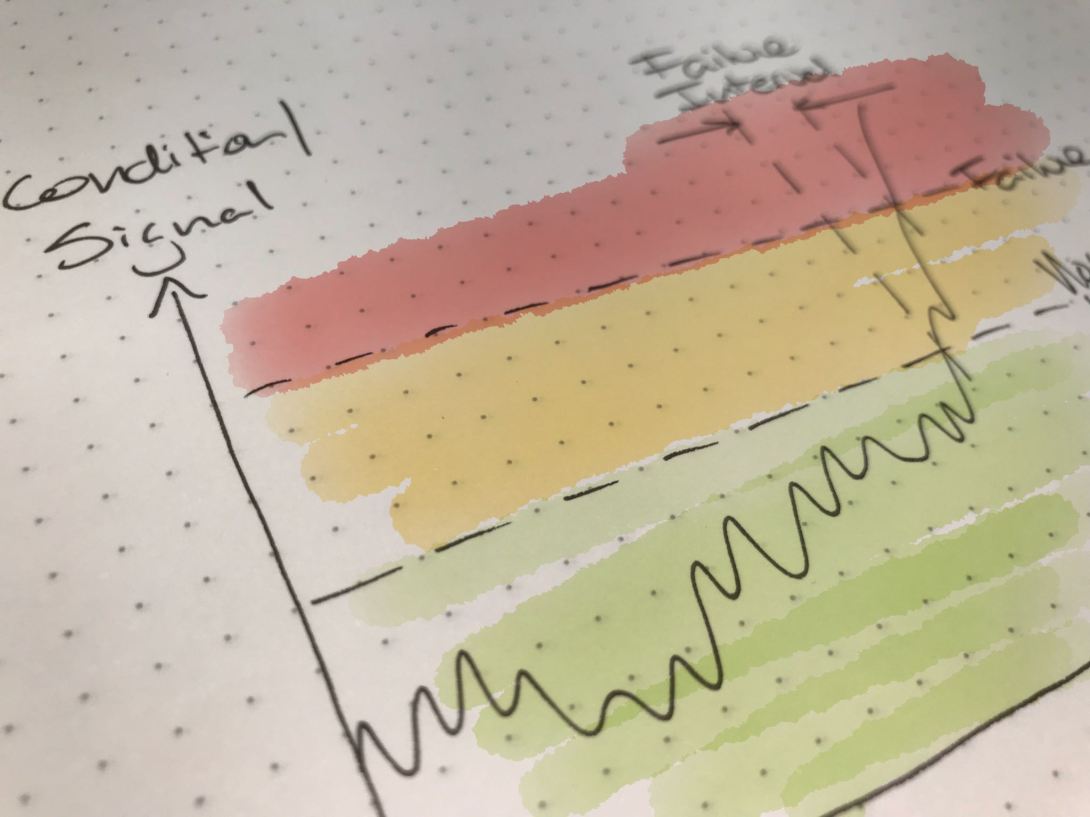

- Predictive – try to identify a signal (a measurable condition) that indicted the probability of equipment failure was increasing (e.g., vibration, metal particles in lubricating oil, gases dissolved in transformer oil), then intervene when this signal reached a certain threshold to refurbish or replace the equipment thereby resetting the equipment’s condition

Predictive was the best strategy, particularly for equipment that was critical to safety, environmental protection or productivity. A predictive maintenance strategy allowed intervention before failure occurred (reducing unplanned downtime) while avoiding the replacement or refurbishment of equipment that was old but in good condition (reducing planned downtime and maintenance effort).

But there were problems. Condition monitoring equipment had to be retrofitted (e.g., gluing vibration monitoring points onto rotating equipment). Readings were gathered manually by technicians who lugged measuring equipment around the plant. That measuring equipment had to be regularly calibrated. Data was only gathered periodically – maybe monthly. The resulting data was stored in proprietary, stand-alone databases where it could only be accessed and interpreted by highly trained specialists. Those specialists were human and their predictions were not always reliable.

That was 20 years ago. Now technology is becoming mainstream that solves these problems.

- Low cost sensors that measure condition almost anywhere – even jet engines in flight

- Communication networks that communicate data from the field (or the air) in near real time

- Systems that can ingest and analyze very large volumes of data in a very small amount of time

- Artificial Intelligence that can find correlations between measurable conditions and incipient failure that even expert technicians cannot see

These technologies – Big Data, IIoT and AI for the jargonista – will revolutionize the field of Asset Performance Management.

General Electric’s recent acquisition of three vendors in precisely these areas – Bit Stew, Meridium and Wise.io – plus its huge installed base of asset-intensive customers means that GE is poised to lead this revolution.

Now, I wonder if GE can build a robot to go out and replace the failing equipment too!.